Boxed Rear Control Arms

- Apr 3, 2015

Boxed rear control arms

Time: 1-2 hours

Tools: standard socket set, standard wrenches

Cost: $300 (new), $30 (conversion)

Tinware: factory style or aftermarket boxed rear control arms (new bushings included), or weld-in boxing plates (new bushings optional)

Tip: When replacing older rear control arms, use quality polyurethane bushings to help stiffen the rear end and reduce deflection.

Performance gains: positive gripping power to help eliminate wheel hop.

Rear coil spring suspensions are extremely simple in design and easy to understand. Along with the shock absorbers and springs, the rear upper and lower control arms receive the torque and weight coming from the front of the vehicle and transfer it downwards- planting the rear tires to the ground. Inside each end of the arms is a rubber bushing. The lower arms are mounted between the rear axle assembly and the frame. Their primary function is to maintain the fore and aft relationship of the axle to the chassis of the car. On the other hand, the upper control arms are centered and mounted at the top of the axle. They help control the torque loads placed on the axle assembly during driving, braking, and cornering. Together, these components are ultimately responsible for the handling of your vehicle under load.

And speaking of load– everyone who enjoys a slightly-overpowered rear wheel drive car is more than familiar with the ever-present condition of wheel hop. It seems almost entirely inevitable. Just one heavy mashing of the pedal and your rear end is wildly dancing up and down. Not exactly what we would call high performance (or a pretty picture for that matter). The constant tweaking and flexing of an ill-handling, sloppy rear suspension can not only lead to broken parts and failure, but also to substantially slower timeslips at the track.

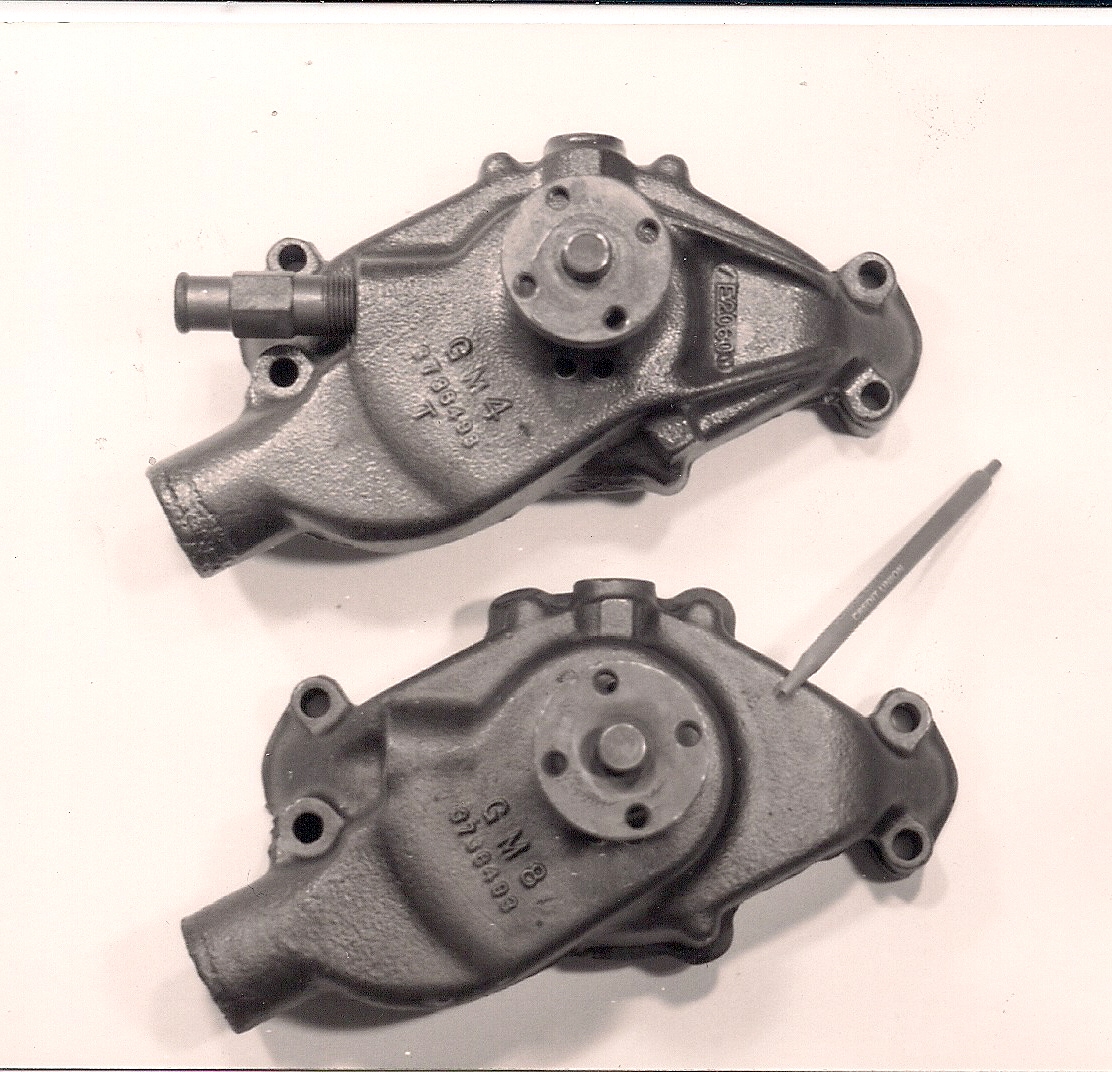

Most factory lower control arms were of the non-boxed sort. This means that one side of the square arm is open. Consequently, that leaves plenty of room for the twisting and distortion of the arms while under torque loads from the axle assembly. The end result is poor, unreliable performance.

By replacing your existing open-style arms with a pair of beefed-up boxed units, you can drastically increase the strength and longevity of your rear suspension. The cool thing about this swap is you have a couple of options. If you need a factory-correct part for restoration accuracy, you should be able to pick up a pair of original arms at any good local swap meet. It goes without saying, but performance aftermarket companies have plenty to offer here as well, most of which are already installed with upgraded polyurethane bushings. Or perhaps if the ol’ wallet is looking a bit thin these days, you can always retrofit your stock arms by welding in the extra support bracing. A pair of properly fitted “boxing” plates sell for around $30. Either way, you really have no excuse not to step up and make the improvement.

To remove your existing lower control arms: With the rear end of the car securely supported on jackstands, loosen and remove the control arm from its rear mounting point at the axle bracket.

Use a socket wrench and a long extension through the frame to access the front mounting bolt of the control arm.

Whether you opted for boxed replacement arms or performed the boxing yourself with weld-in plates, the difference is dramatic. The new and improved arms will hold up far superior than the stock pieces.

Take note: The added boxed side of the arm where the sidewall is flared into a lip should be installed facing the pavement. Additionally, the drilled sway bar holes should be towards the rear of the vehicle.